In this third part of a five-part series, the five members of the Optical Coherence Tomography and Vibrometry Endoscope (OCTAVE) team reveal what were some of the biggest challenges in redesigning a hearing-loss diagnostic tool. They were focused and diligent in their efforts and succeeded in transforming the device from a 20-pound monster to a redesign weighing less than a pound-and-a-half “that people are excited to use.”

“It’s hard to imagine putting that anywhere near a live person.”

That’s how Hyle Park described a device from his lab that could revolutionize how clinicians assess and treat conductive hearing loss.

“It works, but it is pretty heavy and unwieldy,” said Park, a Department of Bioengineering associate professor, of the 20-pound prototype.

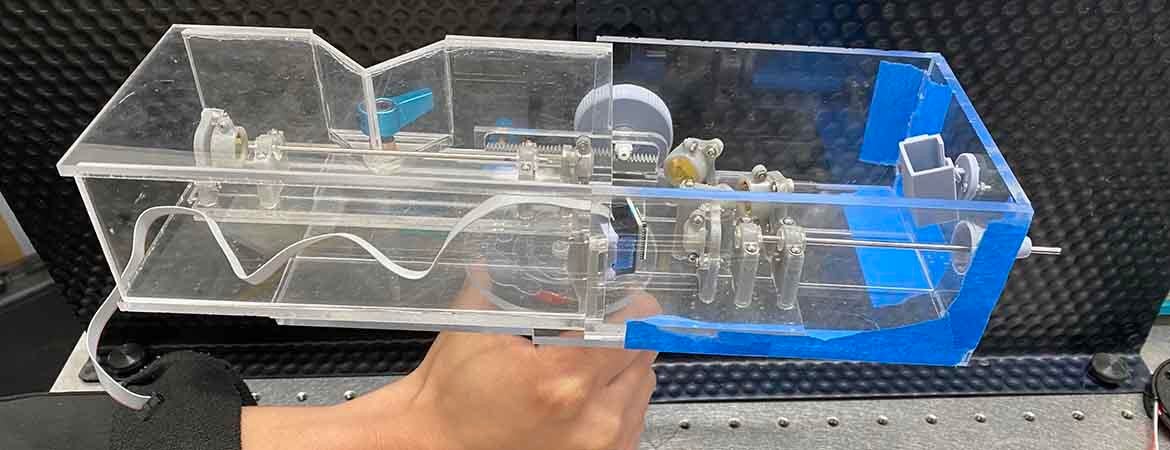

Enter a group of five Marlan and Rosemary Bourns College of Engineering (BCOE) undergraduates. Their task: to shrink the probe’s size while preserving its function. In the end, their redesign weighed in at just 1.32 pounds.

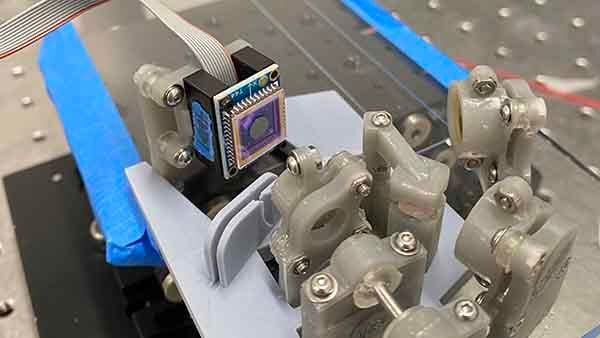

The Optical Coherence Tomography and Vibrometry Endoscope (OCTAVE) uses lasers, mirrors, and lenses to offer a detailed, cost-effective, safe and noninvasive appraisal of the middle ear in real time. OCTAVE is more precise than diagnostic tools such as computed tomography (CT) or magnetic resonance imaging (MRI) scans.

As the team began its work, expectations varied.

“The engineering problem we were trying to solve was so complex,” said project captain Chris Clark, that even the group’s best effort might not yield a successful redesign.

Teammate Minh-Huy (Huy) Tran saw it differently.

“I saw the opportunity to prove that students at UCR are definitely great and can compete with the best in the nation.”

Meanwhile, Park praised the group for quickly sharing a plan to cut the probe’s size by a factor of two to three times.

“I was sold on their potential just a few days into the project,” the associate professor said.

The team spent the early days ensuring solid fundamentals, the middle stretch drawing and 3D modeling, and the final weeks 3D printing, laser cutting, and refining their work, Clark said.

By using “design, build, assess, and iterate … every step of the way” for each of the roughly 200 components in the probe, he said, “our vision for what we could make evolved from something that ‘just about gets the job done’ into a device that people are excited to use and we are proud to show off."

The 10-month process was long, arduous, and rewarding. Students at times worked 40- or even 80-hour weeks on OCTAVE while balancing additional coursework, part-time jobs, family commitments, and more. Some weeks they stalled, flummoxed for a time by a setback or novel problem; other weeks they made progress that was “explosive.

The constants week-to-week were good communication, addressing the task list, and learning with an eye toward clearing the next hurdle. They also conferred routinely with their mentors and academic sponsor, for both technical and real-world feedback.

Once the components were set, the group addressed broader issues, including device-mounting options, the creation of software to control the hardware, and the probe’s overall performance. The software was a critical piece, providing real-time imaging, video, and an easy way for clinicians to link test results with patient records.

Surveyed about the biggest challenges of redesigning OCTAVE, all five team members weighed in:

• Fabricating the prototype

“Some of the precision parts I (had to make) by hand,” Clark said. “It is nerve-racking when you are about to permanently fuse two parts that took hours to produce. You only have one try to do it, and not doing it properly means all the other precision components won't align and the device won't work. There were several such parts and, needless to say, the stress was high.”

• The Brainstorming process

“Each one of us had so many creative ideas,” team member Sofia Gandarilla said. “We found ourselves pressed for time, needing to decide on a few to get started. This required compromise. Thankfully, we were able to agree on the strongest ideas. Over the course of the project, we began to incorporate some of the ideas that we initially tabled. As time went on, the project began to come to life as we incorporated our diverse designs.”

• Keeping a clear focus

“There was so much to do and we all had specific strengths,” said team member Briana Marquez. “Sometimes it got overwhelming and we struggled with delegating and keeping a straight path. This forced us to communicate even more, and we even started teaching each other different skills so we could all contribute more equally. This helped us trust each other more and build our confidence in the team.”

• Creating the software

“The team and I initially pushed back at the idea of having software in the project because we weren’t confident that we would have time to develop it,” team member Tran said. “But with a near-working prototype completed early, we agreed to take on the challenge with the time we had left in Senior Design. With only 10 weeks for me to develop the software rather than 20 weeks, the team and I had decided to develop the software in the winter. I poured my heart into this software, day and night, learning new software skills very quickly to overcome numerous challenges. The most challenging part of the software was being able to render optical coherence tomography (OCT) imaging data simultaneously with fiberscope data in real time. It was a huge roadblock for me. However, through my teammates' support and my motivation to achieve greatness with an amazing team, I was able to find a solution.”

• Design specifications

“I had to consider the manufacturing process to determine the appropriate tolerances between the parts and lens, as well as how to implement rotation adjustability while maintaining the form factor for a portable device,” said team member Alexis Valencia. “Each optomechanical component [the part that holds the optic lens] needed to be strong enough to avoid breaking and rigid enough to prevent optical misalignment over time. To address the alignment challenge, we decided to make a precut stage with slots for all the optomechanical components for the alignment issue, while my task was to create small, precisely fitting feet for each component to ensure they would securely slot into place.”

Through the students’ efforts, hurdles were overcome. The smaller probe was delivered. The project — which earned the team a second-place 2024 National Institutes of Health (NIH) Design by Biomedical Undergraduate Teams (DEBUT) award — was completed.

What’s next?

Clark and Tran continue to refine OCTAVE in Park’s lab. Clark is working to make the machine fully 3D printable, less expensive, and more scalable. Tran is focused on developing and improving the software. Both are in the NIH Concept to Clinic: Commercializing Innovation (dC3I) program. This program is geared to help recipients of the DEBUT award translate their devices to the market.

The pair have interviewed dozens of surgeons and audiologists. This has helped them optimize the probe for clinicians’ needs while also building business knowledge, connections, and prospects for funding.

And Clark has founded a company, OCTAVE Photonics LLC (with the tagline of “Revolutionizing middle ear diagnostics”), that could bring OCTAVE to physicians.

“The journey is going to be difficult and risky so I won't make any promises,” he said, “but Huy and I are putting in everything we've got. If we play our cards right, OCTAVE Photonics LLC might become a successful medical device startup company.”

Is the redesigned probe now suitable for use on a live person?

Park confirmed that he’d use it on his own mother.

This story is the third part in a five-part series. You can read the other parts below:

The Sound of Success Part 1 - How a team of bioengineering students turned a Senior Design project into an innovative diagnostic tool for hearing loss

The Sound of Success Part 2 - Student engineers say friendship, adventure marked their experiences designing a hearing-loss innovation

The Sound of Success Part 4 - Faculty and industry support were critical in helping bioengineering students reap the rewards of their redesigned device

The Sound of Success Part 5 - Award-winning team of bioengineering students share the success factors that helped them achieve "nothing short of extraordinary.

Header image: A close-up image of the Optical Coherence Tomography and Vibrometry Endoscope (OCTAVE) during one of its design and testing stages. (All photos courtesy of the OCTAVE team.